How To Repair A Broken Rocker

Last Updated on April half-dozen, 2022

Rocker arms are a lesser-known but crucial part of some types of internal combustion engines. Their deterioration can cause weak engine performance or fifty-fifty failure, so it's of import to know when replacement is necessary and how much the rocker arm repair price will set up you back.

Demand firsthand aid for your machine trouble? Chat online with an expert:

What is a Rocker Arm and How Does It Work?

Rocker arms are typically located between the pushrod and intake and exhaust valves. They are pushed and pulled by pushrods to "rock" upwards and downwardly, opening and endmost the frazzle valve and intake valve of the combustion sleeping accommodation on engines with a camshaft beneath the engine.

Pushrods move up and downwards every bit the camshaft below them rotates, driven past the crankshaft. In this way, power tin can flow from the combustion bedchamber of the engine through diverse parts to the wheels to put the vehicle in motility.

With broken or loose rocker arms, the exhaust valves and intake valves can't part correctly and the cylinder associated with the faulty rocker arm volition exist disabled. This will ultimately limit the operation of your engine and your ability to drive the car smoothly and safely.

Related: SOHC vs DOHC vs Cam-in-Block Engine

Common Symptoms of a Bad Rocker Arm

Your engine may showroom ane or more of the post-obit symptoms if one or more rocker arms is failing. Although, in that location may be another defective office causing the problem.

Regardless of the cause, the problem should be resolved by yourself or a mechanic before the vehicle is driven once again.

#1 – Clicking or Ticking Noises

Unusual noises involving valves often sound like a rapid clicking or ticking, similar to a sewing machine. You should inspect the rocker arms and surrounding parts while the engine is running if you hear this dissonance. Faulty rocker arms tin can get stuck or ineffectively open and close the valves.

At that place are many other possible causes of strange noises in the combustion chamber and surrounding parts, such as lack of lubrication between moving parts, warped valves, and worn camshaft lobes.

If the rocker arms appear to exist working well on visual inspection, a scrap of troubleshooting done by yourself or a mechanic is the adjacent step to solving the trouble.

#2 – Weak Engine Performance or Stalling

Careful timing is everything to a functional internal combustion engine. For maximum efficiency, valves must open up and close at merely the right time. If the vehicle's faulty rocker arm is getting in the mode of this process, yous'll discover decreased power and poor dispatch.

In severe cases, the engine tin endure to the point of stalling while driving. Somewhen, the vehicle won't fifty-fifty beginning until the cleaved component is replaced.

#3 – Check Engine Light On

The vehicle will recognize weak engine performance equally well, and will warn the commuter by illuminating the check engine light. This signal should never be ignored. You'll want to utilise a diagnostic scanner to check for any stored codes.

Some examples of rocker arm related DTC codes include P2646 (A rocker arm actuator system performance or stuck off bank 1), P2647 (rocker arm oil pressure switch), and P2662 (B rocker arm actuator sys stuck on banking company 2)

#4 – Concrete Deterioration

Visual inspection of the rocker arms can also reveal any cracks or wear. After removing the valve comprehend, wait for pieces of metal below the rocker arms, every bit they can grind on the pivot point and valves when they are in poor condition.

Degraded rocker arms should be replaced even if no other symptoms are present, considering problems will soon follow.

Replacement and Repair Cost

A single rocker arm itself costs betwixt $15 and $60 depending on the vehicle and whether it'south an intake or exhaust rocker arm.

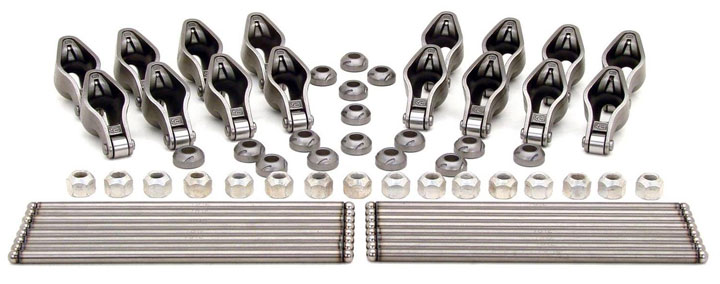

Rocker arm kits, which typically toll between $100 and $500, include other necessary components similar guide plates and pushrods, and may be the better fashion to get if yous are confident that y'all can perform the replacement task yourself.

Often the rocker artillery all neglect around the same time, so replacing them all at once would be a good idea. This makes the full kits the well-nigh common buy option.

Considering rocker arm repair is tedious work, it tin can be fourth dimension intensive so hiring an auto mechanic or dealership to do the job is non cheap. Expect to pay anywhere from $500 to $1,500 (parts + labor) depending on the vehicle.

A practiced clamper of the expense is for labor as it can accept a long time to access the necessary parts. Taxes and fees may increase the m total.

Which Blazon of Rocker Arm to Buy?

Rocker arms are often made from stamped steel, which is basically flat sheet metallic that was put through a stamping press and then shaped by a die. Steel is inexpensive while still beingness strong and fairly lightweight, and thus is a good option for economy cars.

Loftier-performance vehicles usually use aluminum rocker arms, as they are much lighter. Truck engines frequently require even stronger rocker arms made from forged carbon steel or cast iron.

Some inquiry is necessary to know which rocker arm to purchase if yous are doing the job yourself. Automotive parts stores may stock the needed kit for your vehicle, or may be able to special-order parts.

Source: https://cartreatments.com/rocker-arm-symptoms-replacement-cost/

Posted by: martinezwitow1947.blogspot.com

0 Response to "How To Repair A Broken Rocker"

Post a Comment